The 1100°C SiBrick is being developed to power the Company’s SiPHyR™ reactor, enabling low-cost hydrogen production using methane pyrolysis. This model has already demonstrated durability through more than 200 cycles between 700-1200°C.

The 1400°C SiBrick is designed for use in ultra-high temperature industrial applications such as alumina calcination and cement production. It has been successfully cycled between 1000-1500°C, demonstrating stability under demanding conditions.

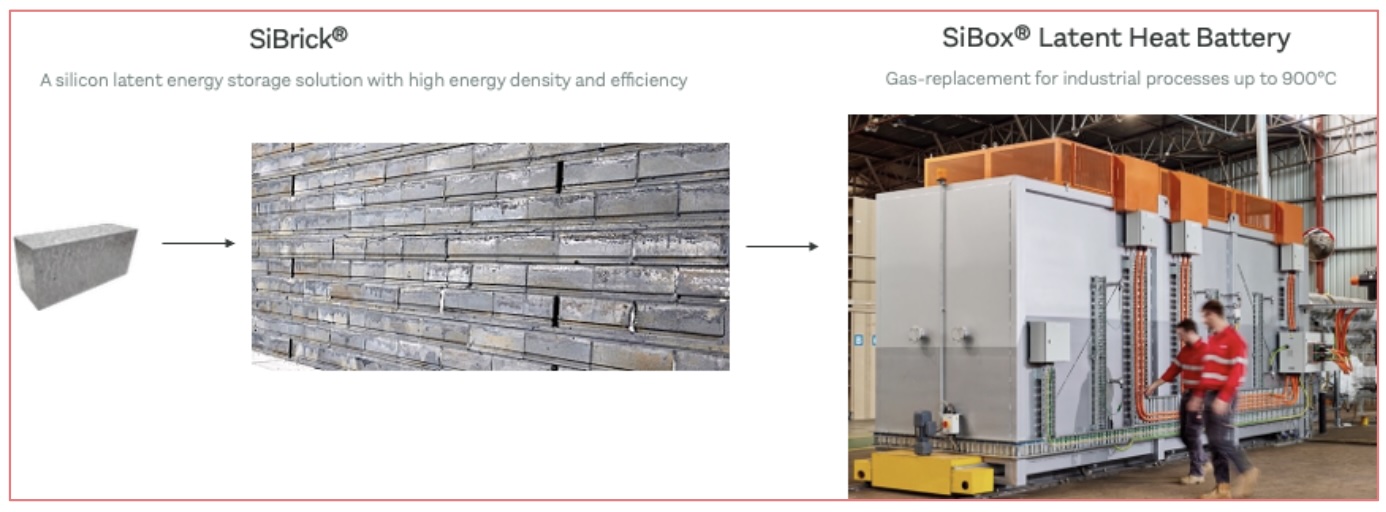

In parallel, 1414 Degrees is developing additional SiBrick variants optimised for integration into its SiBox® long-duration energy storage systems, which deliver stable heat flows within ±2°C across the 200–900°C operating range.

These results strengthen the pathway to mass production of SiBrick, a critical enabler of 1414 Degrees’ Heat-as-a-Service (HaaS) business model and hydrogen technologies, creating scalable revenue opportunities as industry transitions to low-carbon energy.