Unveiling an integrated platform for next-generation battery materials

We have announced a significant technological breakthrough that positions us as a key player in the rapidly expanding battery materials sector. The integration of our SiNTL™ and SiPHyR® technologies opens a pathway to high-performance graphitic anode material for lithium-ion batteries.

Our collaboration with the George Washington University has identified a potential single-step manufacturing process that could transform a hydrogen production by-product into premium battery material while simultaneously reducing production costs.

Streamlining Battery Material Production

Our integrated approach combines SiNTL aluminium-coated silicon nanoparticles with carbon generated from our SiPHyR methane-pyrolysis reactors. This represents a significant departure from conventional technologies that rely on crystalline silicon requiring protective coating layers applied in separate steps before being mixed with graphite.

Our integrated approach may lower production costs by eliminating multiple coating and mixing steps typical of conventional processes. By controlling both proprietary silicon technologies, we maintain oversight of intellectual property and the supply chain across this emerging value proposition.

Massive Market Opportunity

Our strategic timing aligns with explosive growth projections for the silicon-anode battery market, forecast to expand from USD $536.5 million in 2025 to more than USD $20.8 billion by 2034. This represents a compound annual growth rate exceeding 50 percent, underscoring demand for technologies that improve performance, scalability and cost-effectiveness.

Development Timeline

We’ve outlined an ambitious testing schedule in collaboration with the George Washington University, with laboratory facilities to be upgraded to accelerate development and testing protocols.

Additional battery test channels are being established to increase the number of anode cells that can be cycled up to 1,000 times. Our development roadmap targets properties of approximately 500 mAh/g for graphite-silicon composites within three months, escalating to 600 mAh/g within twelve months as silicon nanoparticle content increases.

These materials will be prepared for testing by battery Original Equipment Manufacturers (OEMs), a critical step toward commercial validation.

Building an Integrated Silicon Ecosystem

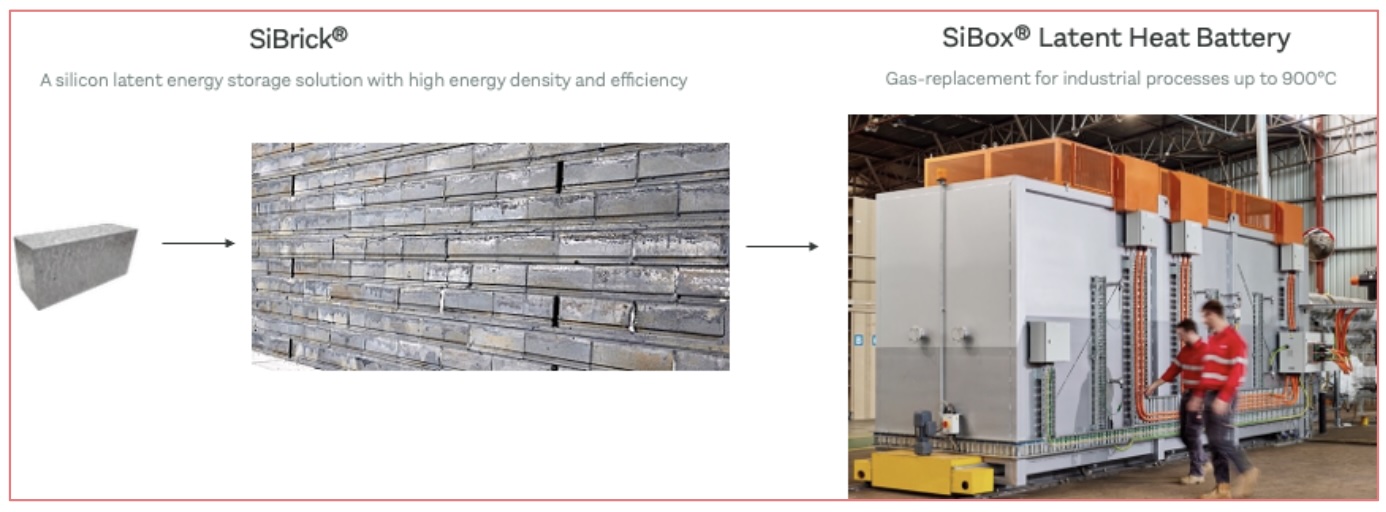

The SiNTL technology acquisition has expanded our portfolio into a comprehensive suite of silicon-based energy and materials technologies. Our SiBrick® thermal energy storage platform serves as the foundational enabler, storing renewable electricity as high-temperature heat.

This thermal backbone powers both our SiBox industrial heat replacement system and our SiPHyR hydrogen production platform. The addition of SiNTL nanotechnology for battery anodes creates potential for multiple revenue streams across renewable heat, clean hydrogen and advanced battery materials.

Our SiBox system can potentially support pre-processing or sintering of SiNTL anode material at temperatures exceeding 2,000°C, further demonstrating the synergies within our integrated technology platform.

Next Steps

We will be producing combined SiNTL-SiPHyR anode materials for rigorous testing and validation. Success in meeting our stated performance targets could position us to capitalise on the surging demand for advanced battery materials as the global energy transition accelerates.